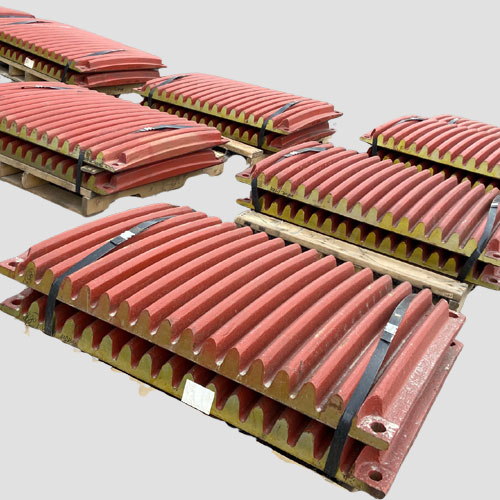

Liners

Our liners offer longer wear life, fast work-hardening properties and reliable change-out scheduling.

NCIndustrial is a supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operatives, we provide crusher liners with advanced designs and alloys exclusively developed for each application. Our experienced sales and engineering departments work closely with clients to understand their needs. As an ISO 9001 certified company, strict QA and QC programs are in place at each stage of fabrication. Contact our sales department to request more information about NCIndustrial’s cone crusher liners.

NCI manufactures 14%, 18% and 21% manganese crusher liners for different requirements.

With 50 years of combined experience in casting business, we are determined to produce the finest manganese liners and we are proud to put our name on our products. We offer liner consulting, removal and installation procedures and services, seating pad inspection and repair and troubleshooting.

At NCI, we service all makes and models of crushers.

Liners

- METSO, HP, GP & C-SERIES JAWS

- NORDBERG-SYMONS

- ALLIS-CHALMERS

- PARKER

- SANDVIK

- SVEDELA

- CEDARAPIDS

- TEREX

- KPI

- FULLER TRAYLOR

- HEWITT ROBBINS

- KLEEMANN REINER

- PIONEER

- TELSMITH

- CLEMRO AND MORE

Liner Accessories

- BACKING COMPOUND

- WAX

- TORCH RINGS

- LOCKING NUTS

- CUSTOM POURING GATES

- CRUSHER GAPPING SLUGS

- WEAR GAUGES

- COMPOUND SEALING SOLUTIONS

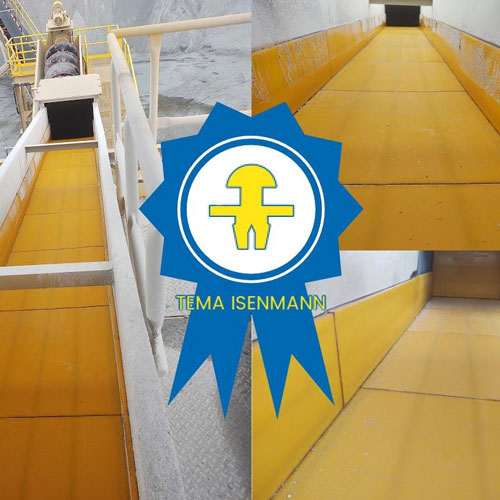

Magnetic Liners

TEMA Screen Panels: Our custom cast liners are designed to fit perfectly, and the rare earth magnets adhere effortlessly, eliminating the need for cutting or bolting for ease of installation.

NCI is the distributor for the full line of Tema products.

- Polyurethane screen panels. Both Injection molded and Open Cast Process (greatly extends wear life)

- Trommel panels & dams (as well as Trommel Screens)

- WS2.10 Magnetic Chute liners

- WS2.10 Patented Magnetic Custom Wear Solution

- Wedge wires

- Spray Nozzles

Contact

100 Mumford Road

Lively, Ontario P3Y 1L2

P 705-885-1600

F 705-885-1644

E sales@ncindustrial.ca

EMERGENCY + AFTER HOURS

P 705-885-1600 ext. 9

Questions / Inquiries

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.